1. Introduction

It's estimated that around 20% of all small-molecule pharmaceuticals currently in use contain halogens. The presence of carbon-halogen bonds can significantly enhance various properties, such as thermal and oxidative stability, as well as improve the permeability of biological membranes. In drug discovery, natural products (NPs) are highly valued for their unique scaffolds, and halogenation can further optimize their characteristics. Previous studies have shown that chemical halogenation of plant extracts can yield bioactive compounds. Building on this, a generic halogenation strategy was developed to create libraries of novel halogenated NPs, particularly for identifying new antifungal agents. Initially, the halogenation reaction was carried out using a series of NP standards from diverse chemical classes. Once successful, the same process was applied to various plant extracts (using bromine and iodine). This approach aimed to discover halogenated NPs with enhanced antifungal activity.

Â

2. Oxidative Halogenation of Natural Products

In this project, we focused on developing an eco-friendly halogenation reaction that uses sodium halides in an aqueous hydrogen peroxide solution. This method was applied to both pure NPs and crude plant extracts to evaluate whether it could boost their antifungal activities. Our goal was to explore the potential of this green chemistry approach to create novel compounds with improved biological properties.

Halogenation Procedure

- For chlorination: 6 equivalents NaCl, 1g of standard compound, 6 equivalents H2O2, 10mL acetic acid, diluted to 25mL with water.

- For bromination: 6 equivalents NaBr, 1g of standard compound, 6 equivalents H2O2, 10mL acetic acid, diluted to 25mL with water.

- For iodination: 3 equivalents NaI, 1g of standard compound, 6 equivalents H2O2, diluted to 25mL with water.

- Reaction time: 24 hours

- Conducted at room temperature

- Under magnetic stirring

- Eco-friendly conditions

Â

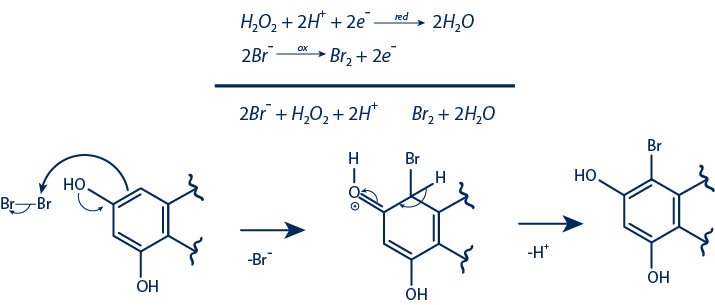

Chemical Reaction

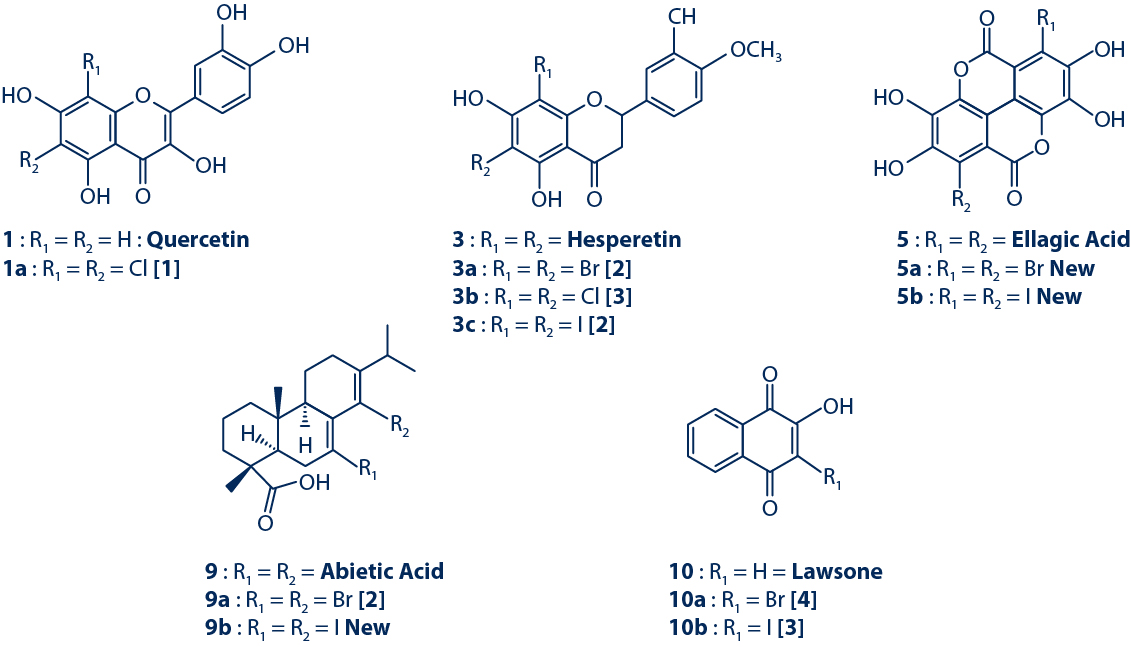

Semi-Synthetic Compounds Obtained from Oxidative Halogenation

Yields ranged from 0.7% to 29%

We selected a series of NP standards with different scaffolds for halogenation. Each compound was tested at 50 mg. The purification of the halogenated derivatives was achieved through reverse-phase semi-preparative HPLC-UV.

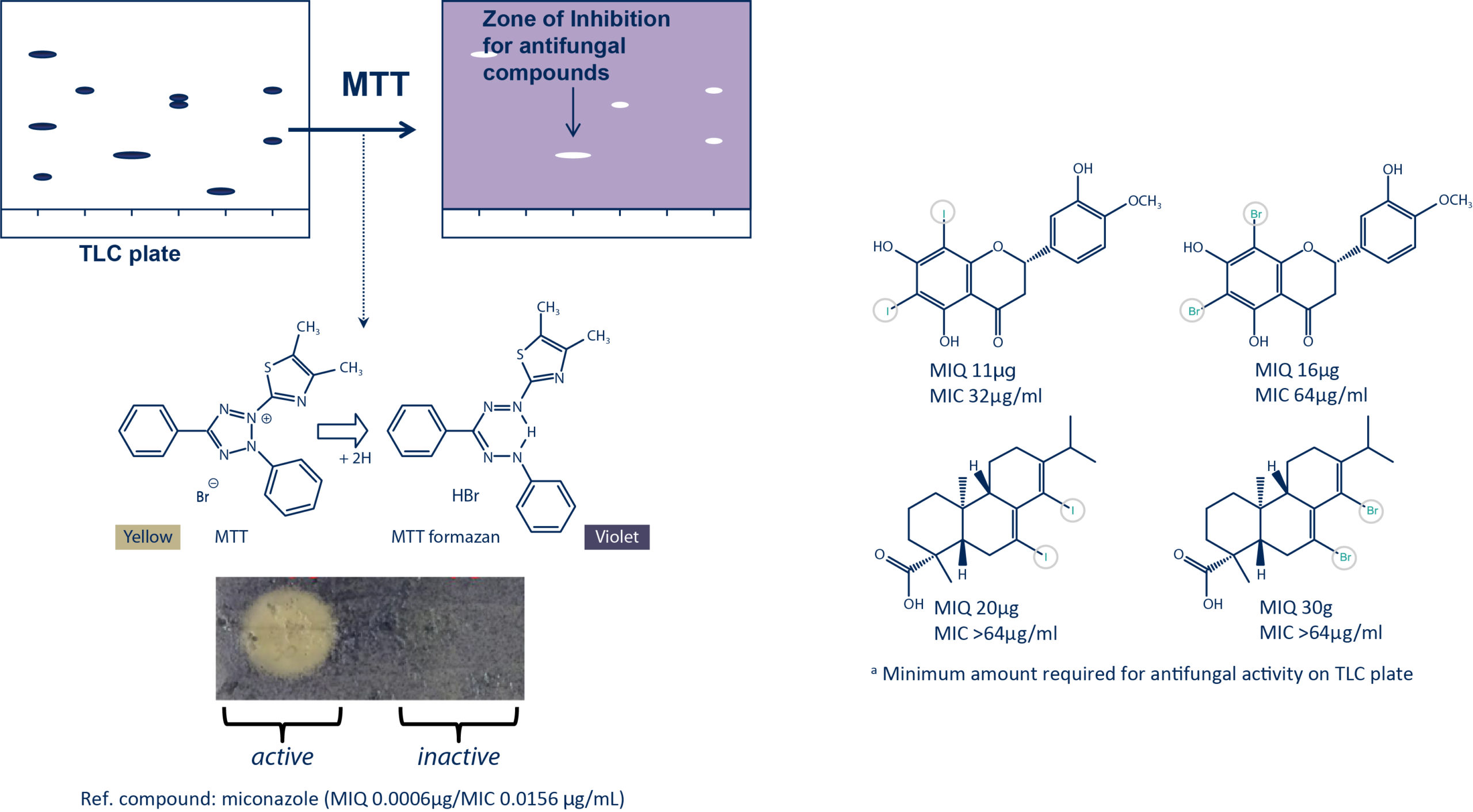

3. Antifungal Assay Against C. albicans

The antifungal activity of the purified halogenated derivatives was assessed against C. albicans using both the bioautography assay (MIQa) and the dilution assay (MIC).

C. albicans

Strains:

CAF 21

DSY 2621

Antifungal Bioautography Assay

Â

4. Selection of Crude Extract Rich in Flavonoids

Citrus Species Account for 8.5% of World Fruit Production

40-60% of oranges are used for juice production 50% of the pericarp makes up the total weight |

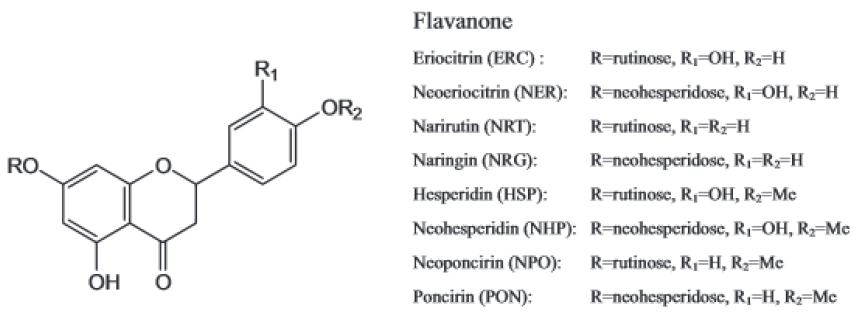

After validating the halogenation reaction with the series of standards, the methodology was applied to a model crude plant extract (Citrus sinensis pericarp), which is rich in flavonoids and readily available at a large scale. |

Citrus sinensis Pericarp Constituents

| Components | wt% on the basis of dry weight |  |

| Ash (%) | 2.56 | |

| Sugar (%) | 9.57 | |

| Fat (%) | 4.00 | |

| Protein (%) | 9.06 | |

| Flavonoid (%) | 4.50 | |

| Pectin (%) | 23.02 | |

| Lignin (%) | 7.52 | |

| Cellulose (%) | 37.08 | |

| Hemicellulose (%) | 11.04 |

Â

5. Bromination of the Citrus Pericarp Methanolic Extract

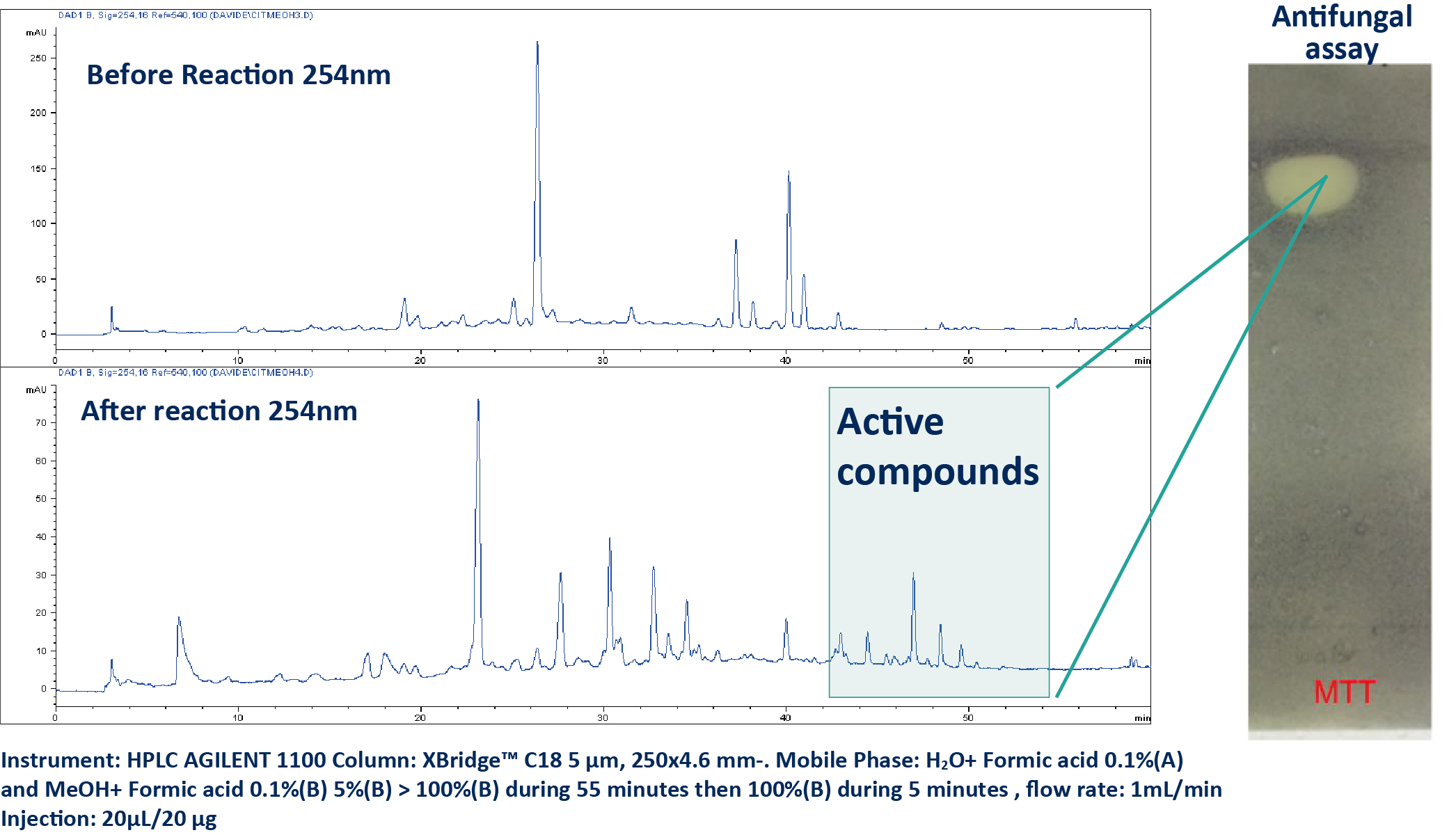

The bromination of the methanolic extract was initially carried out at the analytical scale using 100 mg of the extract over 24 hours. Afterward, the reaction was halted and monitored via HPLC-UV (A). The crude reaction mixture exhibited significant antifungal activity against C. albicans.

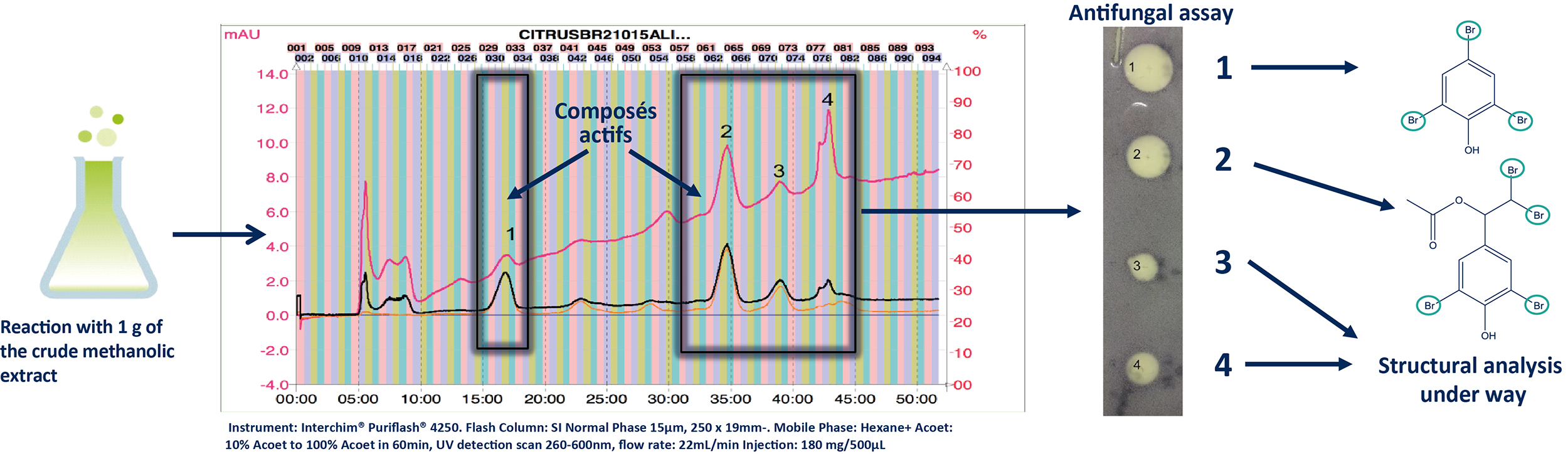

To isolate the active compounds, the reaction was scaled up to 1 g while maintaining the same reaction time (24 hours) (B). The reaction mixture was dried and purified using normal phase flash chromatography (FC). The preparative conditions were first optimized at the analytical scale before being transferred to the preparative scale using the same stationary phase. The fractions obtained were dried and subjected to antifungal assays, leading to the identification of four active compounds (1-4). The structural elucidation of these compounds was performed using HRMS and NMR.

a. HPLC UV Analysis of the Crude Extract Before and After Reaction

b. Normal Phase Ultra Pressure Flash Chromatography (FC-UV)

Â

6. Conclusion

The halogenation of a series of NP standards proved effective in generating antifungal compounds against the human fungal pathogen Candida albicans. The reaction was performed under eco-friendly conditions using mild reagents. The methodology was also successfully applied to the halogenation of a complex crude plant extract derived from a waste material (citrus pericarp), resulting in unusual antifungal halogenated derivatives.

These preliminary findings further highlight the potential of chemical halogenation of plant extracts to produce bioactive 'unnatural' natural products. In this context, applying such reactions to crude extracts from waste biomass could be highly beneficial for creating valuable bioactive NPs.

The next steps involve evaluating the halogenated derivatives against various biological targets and expanding this methodology to a broader range of plant extracts with chemically diverse compositions.

Â

7. References

1. Herrera-Rodriguez et al. Chem Today 2011;29:4

2. Mendez et al. ACS Comb Sci. 2011;13:200-204

3. Bernini et al. New J Chemi. 2015;39:2980-2987

4. Favre-Godal et al. Phytochemistry 2014;105:68-78

5. Challal et al. Planta Med. 2015; 81: 1636-1643

Â

Learn More:

|

|

Guangzhou Green Health Pharmaceutical Technology Co., Ltd. commited to build health and beauty,it is a High-tech intergreted enterprise company include research developing,manufacturing,market sale and OEM. We focus on product research,development and utilize scientific research industry since the company established.The company brings together the technical elites of biological research institutes and colleges and universities. In terms of product development and research, it is among the best in the industry in terms of raw materials, formulas and technologies.Relying on strong technical strength and professionalism, we are a gold medal partner for various e-commerce and shopping."Excellent quality, competitive price, efficient service" is our slogan to undertake commissioned processing, to help you win in the fierce market competition.We mainly engaged in the business scope of solid beverages, tablets, gummies, capsules, enzyme jelly, Liquid Drink and other new products development, production, packaging, sales and OEM one-stop service. Guangzhou Green Health Pharmaceutical Technology Co., Ltd.,strength and product quality have been recognized by the industry.We welcome friends from all walks of life come to visit, guide and negotiate business.

Hyaluronic Acid Gummies,Ashwagandha Gummies,Fertility Gummies

Guangzhou Green health Pharmaceutical Technology Co.,Ltd , https://www.greenhealthfactory.com